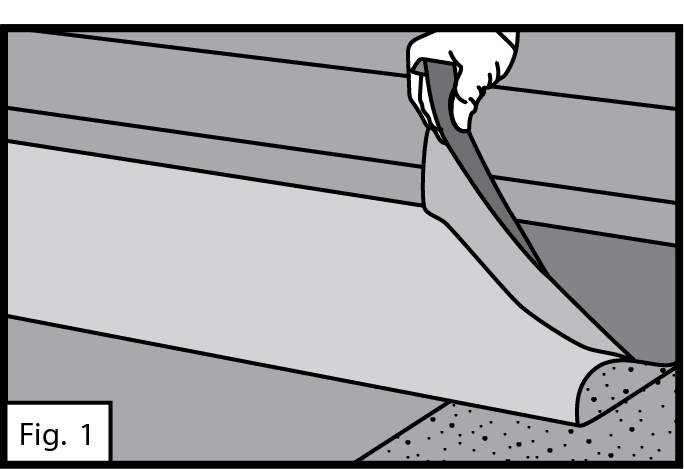

Fold the aligned sheet back half way exposing the release liner. See Fig. 1.

Step 6

Peel release film at a 45° angle in a constant motion, while firmly holding the half of the sheet that is in contact with the roof in place as the liner is removed. See Fig. 1.