Step 6

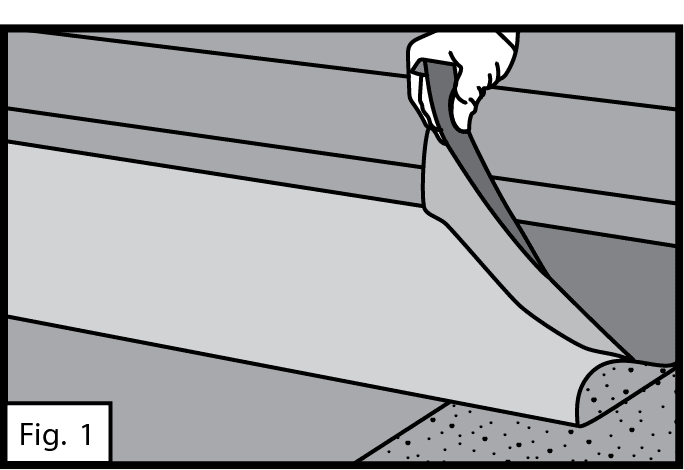

Remove release liner at a 45° angle in a constant motion, while firmly holding the half of the sheet that is in contact with the roof in place as the liner is removed. See Fig. 1.

Now that the release liner is removed, roll the sheet and press firmly into place.

Now roll the opposite half of the sheet back and remove the release liner using the same method as above.

If additional pieces are needed to complete the starter course, the end lap to be overlapped must be cut at 45° angles on the top and bottom corners. See Fig. 2.

The top corner on the piece that is overlapping the previous piece must also be cut on the top corner at a 45° angle. See Fig. 2.

The overlap is to be 6 inches. Remove the release liner and adhere as with the previous sheet.

Remove the side lap selvage edge release film on the area to be overlapped.

Do not remove the remaining release film covering the side lap selvage edge at this time.